|

|

|

||||||||

|

|

|||||||||

| Home | Forums | Register | Gallery | FAQ | Calendar |

| Retailers | Community | News/Info | International Retailers | IRC | Today's Posts |

|

|

|

Thread Tools |

|

|

#1 |

|

TM Desert Eagle Slide Woes

Hey Doc(s),

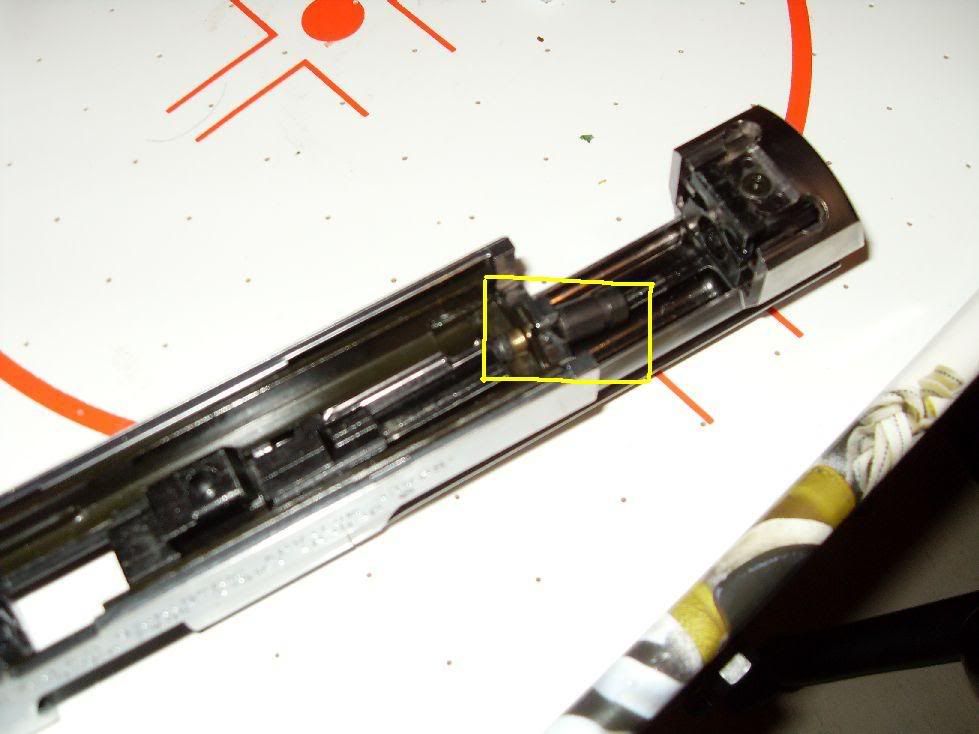

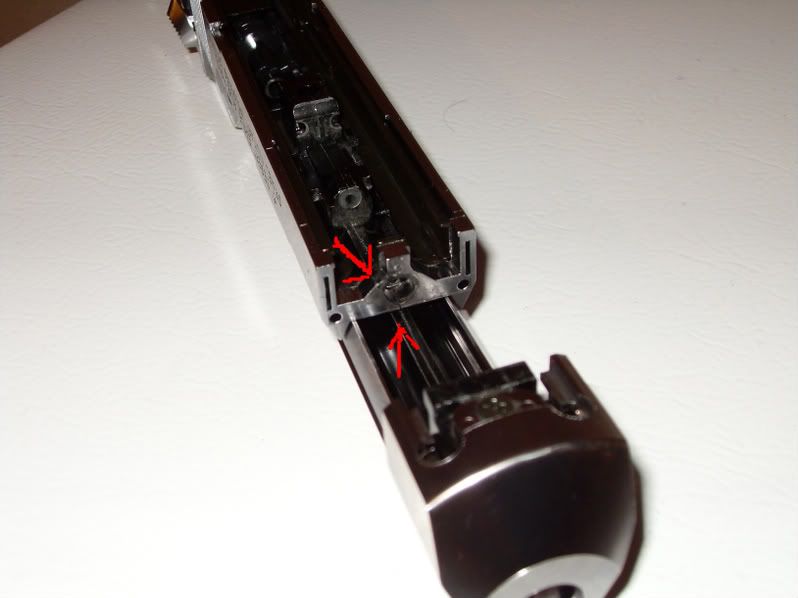

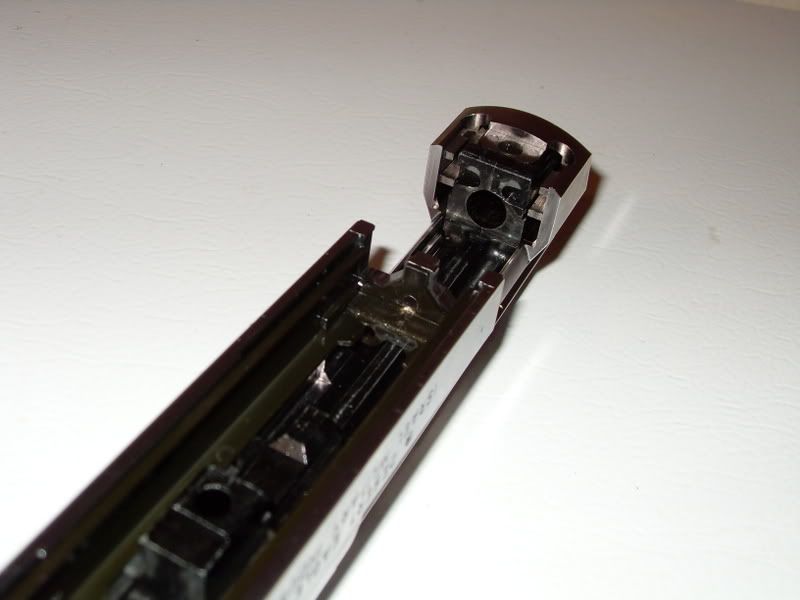

First off, I apologize if i don't always use the proper terminology, but I'll try to keep that to a minimum. Anyway, I've been having trouble with my Deagle(Hard Kick) lately in which at times, when I cock or fire the gun the slide doesn't fully return to it's original position, but remains about a centimeter back. I think I've narrowed the problem to part 50AE-26 and it's accompanying screw/bits 50AE-13 and 50AE-14. (as shown in the picture)  The problem is, these pieces often get loose after I go through a couple of mags thus hitting the edges of the hole it slides in and out of. I often find myself stripping the gun in order to re-tighten the bits. Is there a way of fixing this problem? I was thinking of removing them completely, as I do not think they add to the functionality of the gun, but then again I may be wrong. Any help is greatly appreciated. -----UPDATE----- So I decided to unscrew the part to take a better look, and I found out that it was the actual plastic frame that was cracked along the threading However the metal frame underneath is still in one piece:  Part 50CS-3 crack along the hole  The metal slide underneath is in one piece though. (Thankfully) Last edited by NoobSchoolBus; August 6th, 2008 at 12:16.. Reason: Real problem found |

|

|

|

|

|

|

#2 |

|

Vicious MSPaint Wizard

|

Contact Tirador for replacement parts if needed.

|

|

|

|

|

|

#3 |

|

a.k.a. Egria

|

That part is a bitch to get back on securely. I would recommend that you clam down the metal part really tight and then put some loctite on the screw and screw it tightly back in. That should hold it. As for functionality, I pretty sure it keeps the slide stable and prevents it from shifting left and right, I may be wrong about that. I've also had some what of the same problem as you, but when I disassembled my slide I found that part 50AE-3 was broken.

__________________

PURVEYOR OF FINE PARACORD PRODUCTS www.beaconconceptsco.com Click Here For ASC Thread Team GHOSTS - G86 |

|

|

|

|

|

#4 |

|

Ugh.. that sucks to hear. I think this may be a last resort (Next to buying a new piece/slide). But if I do go Loctite, I'm guessing to go with the Blue Removable Threadlocker Grades (No. 242.. or maybe 243 since it's oil resistant) because sooner or later, I may want/need to remove the bit.

|

|

|

|

|

|

|

#5 |

|

Tys

|

Yup, blue stuff should do the trick...clean the screw and hole as thoroughly as possible before applying and the lube it up.

The oil resistant stuff is much better...although I've never bothered to use it (viva la HiCapa!). If you're in a jam for some drop by the AEG workshop on Tuesday and I'll have my tool kits with me. Tys |

|

|

|

|

|

#6 | |

|

Quote:

Thanks a lot, Tys. |

||

|

|

|

|

|

#7 |

|

[UPDATE]

Found the problem. (check first post) would Loctite still be the solution for this? or will I be needing another slide? :[ |

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|